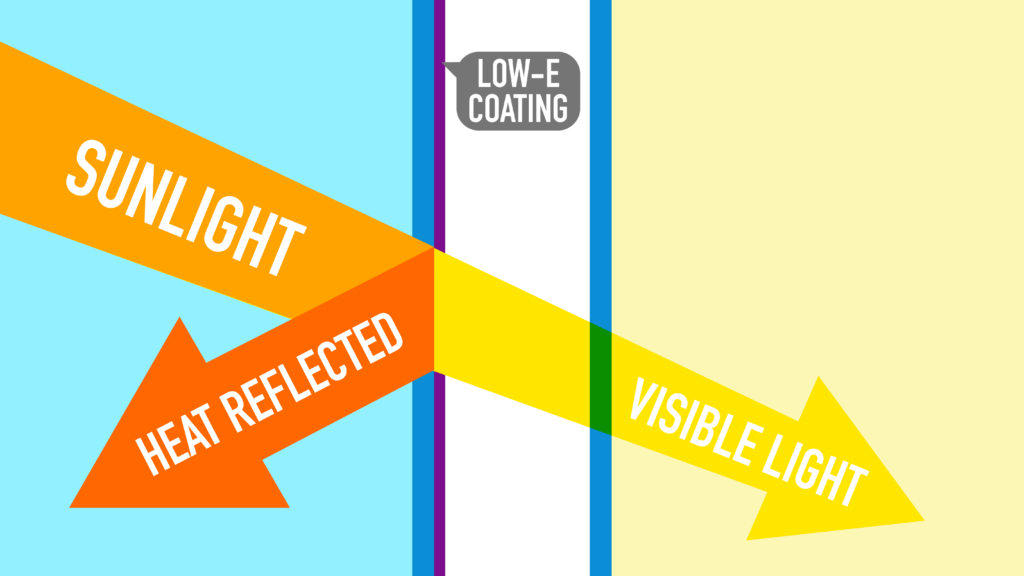

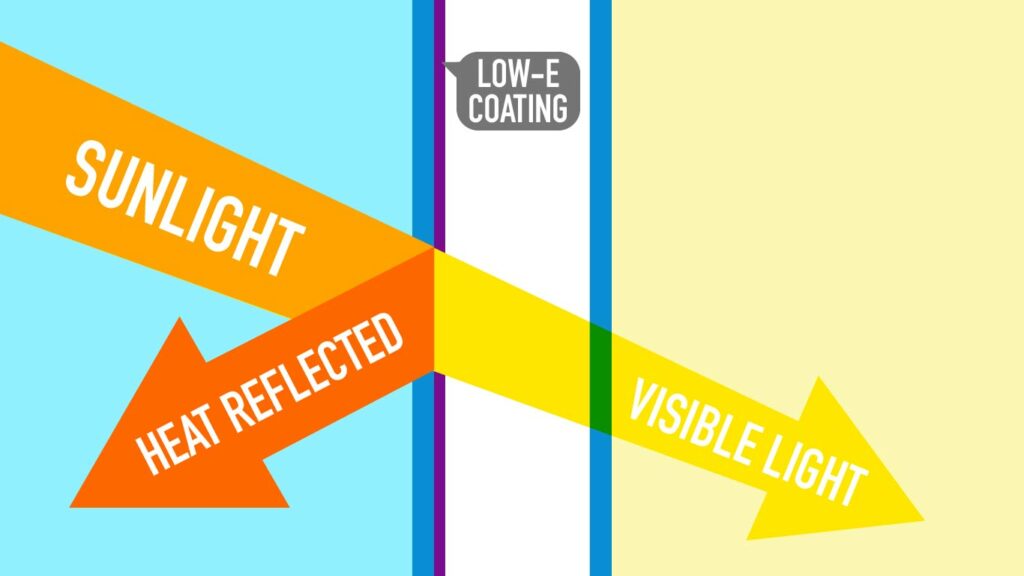

Low-e coatings, short for low emissivity coatings, are a type of thin, transparent film that is applied to the surface of windows to improve their energy efficiency. The coating works by reflecting infrared light while still allowing visible light to pass through the glass. This makes low-e coatings a popular choice for homeowners and businesses looking to reduce their energy costs and improve the comfort of their living or working spaces.

In this article, we will explore the science behind low-e coatings, their benefits, and some of the different types of coatings that are available on the market.

How Low-e Coatings Work

They work by reflecting radiant energy, which includes both heat and light, away from the surface of the glass. Radiant energy is measured in wavelengths, with longer wavelengths associated with heat and shorter wavelengths associated with light. Low-e coatings are designed to reflect longer wavelengths, such as those associated with heat, while still allowing shorter wavelengths, such as those associated with visible light, to pass through the glass.

The coatings are made up of several layers of metallic particles, typically silver or tin oxide, that are applied to the surface of the glass using a vacuum deposition process. The layers are extremely thin, typically less than 1/100th the thickness of a human hair, and are carefully calibrated to reflect specific wavelengths of light.

Benefits of Low-e Coatings

Their primary benefit is their ability to improve the energy efficiency of windows. By reflecting heat away from the surface of the glass, low-e coatings can help to reduce the amount of heat that is transferred into or out of a building through the windows. This can have a significant impact on the building’s energy usage and can result in lower heating and cooling costs.

They can also help to improve the comfort of a building’s occupants by reducing the amount of solar heat gained through the windows. This can help to reduce the amount of glare and hot spots within a building, making it a more pleasant and comfortable place to live or work.

In addition to their energy-saving benefits, low-e coatings can also help to protect furniture, artwork, and other valuables from fading or discoloration. By reducing the amount of UV radiation that is transmitted through the windows, low-e coatings can help to extend the life of these items and keep them looking their best for longer.

Types of Low-e Coatings

There are several different types of low-e coatings that are available on the market, each with its own unique set of properties and performance characteristics. Some of the most common types include:

- Hard-Coat Low-e Coatings – Hard-coat low-e coatings are made by depositing metallic particles onto the surface of the glass while it is still hot. This creates a durable, scratch-resistant coating that can withstand harsh environmental conditions. However, the process is more expensive than other types of low-e coatings, and the coating may not be as effective at reflecting heat as other types.

- Soft-Coat Low-e Coatings – Soft-coat low-e coatings are applied to the surface of the glass in a vacuum chamber at room temperature. This creates a thin, delicate coating that is highly effective at reflecting heat. However, the coating is also more susceptible to scratching and damage and may require additional protective layers to maintain its performance over time.

- Passive Low-e Coatings – Passive low-e coatings are designed to maximize solar heat gain during the winter months while still reflecting heat during the summer months. This makes them a good choice for buildings in colder climates where heating costs may be a concern.

- Solar Control Low-e Coatings – Solar control low-e coatings are designed to reduce the amount of solar heat gain through the windows, making them a good choice for buildings in warmer climates where cooling costs may be a concern.

Choosing the Right Low-E Coating

One of the most important factors to consider when choosing a low-e coating is the climate in which the windows will be installed. In colder climates, a low-e coating with a higher solar heat gain coefficient (SHGC) may be preferred, as this will allow more sunlight to pass through the window and help warm the room. In warmer climates, a lower SHGC may be more appropriate, as this will help block unwanted heat from the sun and keep the room cooler. It is also important to consider the U-factor of the low-e coating, which measures how much heat is conducted through the window. In colder climates, a low U-factor is desirable to reduce heat loss, while in warmer climates, a higher U-factor may be more appropriate to prevent excessive heat gain.

Another important consideration when choosing is the orientation of the windows. South-facing windows will receive more direct sunlight throughout the day, while north-facing windows will receive less. West-facing windows will receive more afternoon sunlight, while east-facing windows will receive more morning sunlight. Depending on the orientation of your windows, you may want to choose a low-e coating with a higher or lower SHGC to maximize energy efficiency. For example, south-facing windows in a cold climate may benefit from a low-e coating with a higher SHGC to capture as much solar heat as possible, while east-facing windows in a warm climate may benefit from a lower SHGC to prevent excessive heat gain in the morning.

Personal preferences also play a role in choosing the right low-e coating. Some low-e coatings have a slightly tinted or reflective appearance, which can affect the look and feel of a room. Some people may prefer a more natural, unobstructed view through their windows, while others may be more concerned with energy efficiency and are willing to sacrifice some clarity for lower heating and cooling costs. It is important to consider all of these factors when choosing a low-e coating and to work with a professional installer who can help guide you through the decision-making process.